About The Product

Direct-Fit OEM Compatible Exhausts

OEM (Original Equipment Manufacturer) compatible exhausts are designed to be a direct replacement for your machinery's factory-installed system. This means no modifications are needed for installation, ensuring a perfect, hassle-free fit every time. We go beyond simple replication by engineering our parts with superior materials and design improvements to deliver enhanced durability and a longer service life, reducing your total cost of ownership.

Precision Engineered

OEM Replacement Exhausts

Our OEM replacement exhausts are a direct-fit alternative to factory-fitted parts and are 100% interchangeable. We offer superior products to improve machine performance and productivity. Our design improvements, premium materials, and heavy-duty manufacturing result in exceptional durability and product life.

Request a Quote

Our Process

Master Parts & Planning

To ensure a seamless fit, we can 3D scan engine pipes, mufflers, and other components. An initial concept is created from the 3D scan data. Our dedicated team works closely with customers to ensure our parts meet their needs.

Our Process

Design & Engineering

Our in-house design team optimises our exhaust systems based on real-world mine site feedback. We create detailed drawings for all our parts for manufacturing. Our exhausts are designed for durability and longevity.

Our Process

Jigs & Manufacturing

Manufacturing jigs ensure our parts are built to spec every time. Our streamlined processes ensure a fast turnaround for our customers. From our extensive range of existing parts to custom fabrication, we have a solution for your fleet.

Our Process

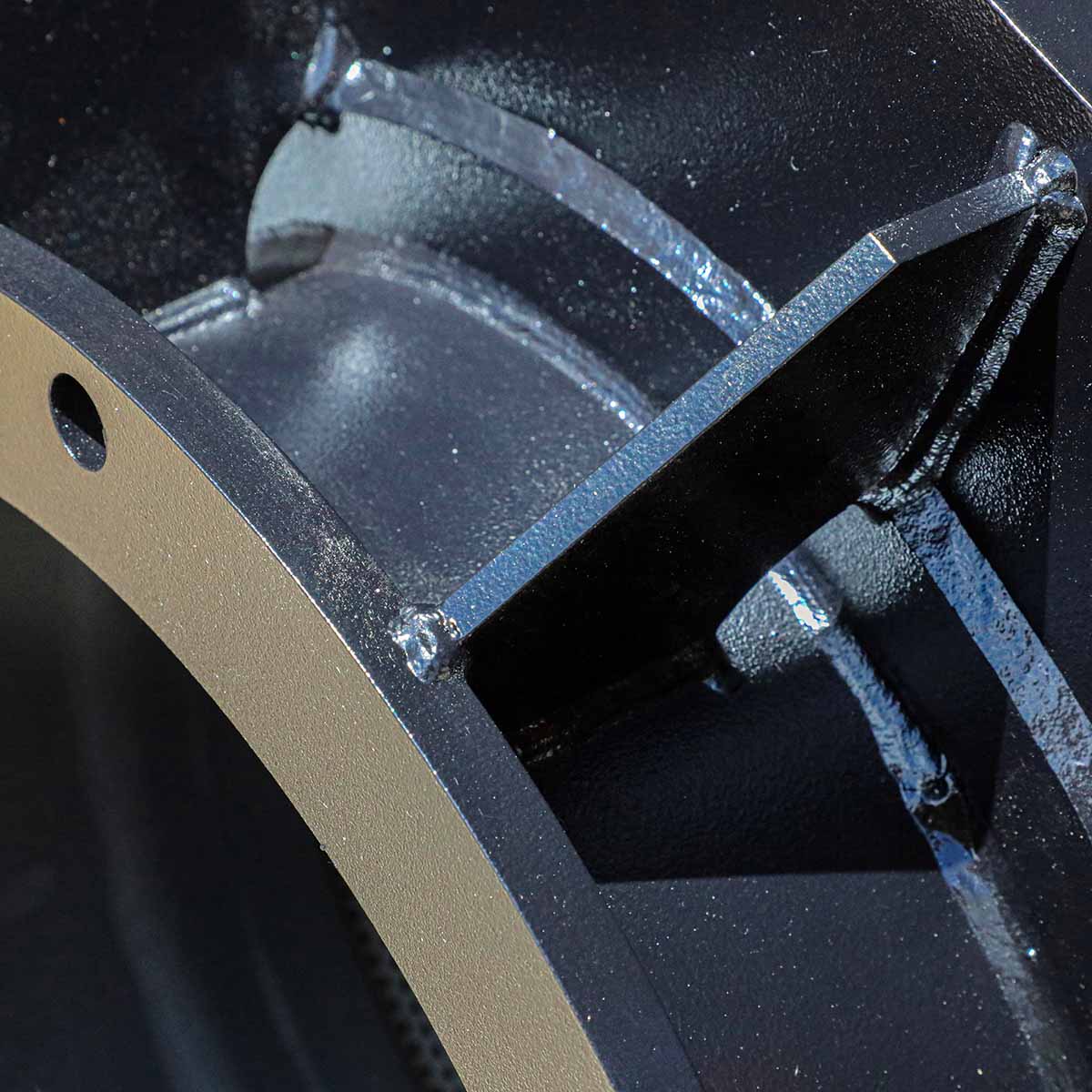

Fabrication & Quality

Our skilled fabricators and boilermakers take pride in their work. We undertake quality inspections at every stage of the manufacturing process. The final inspection ensures our parts are ready for dispatch.

Our Work

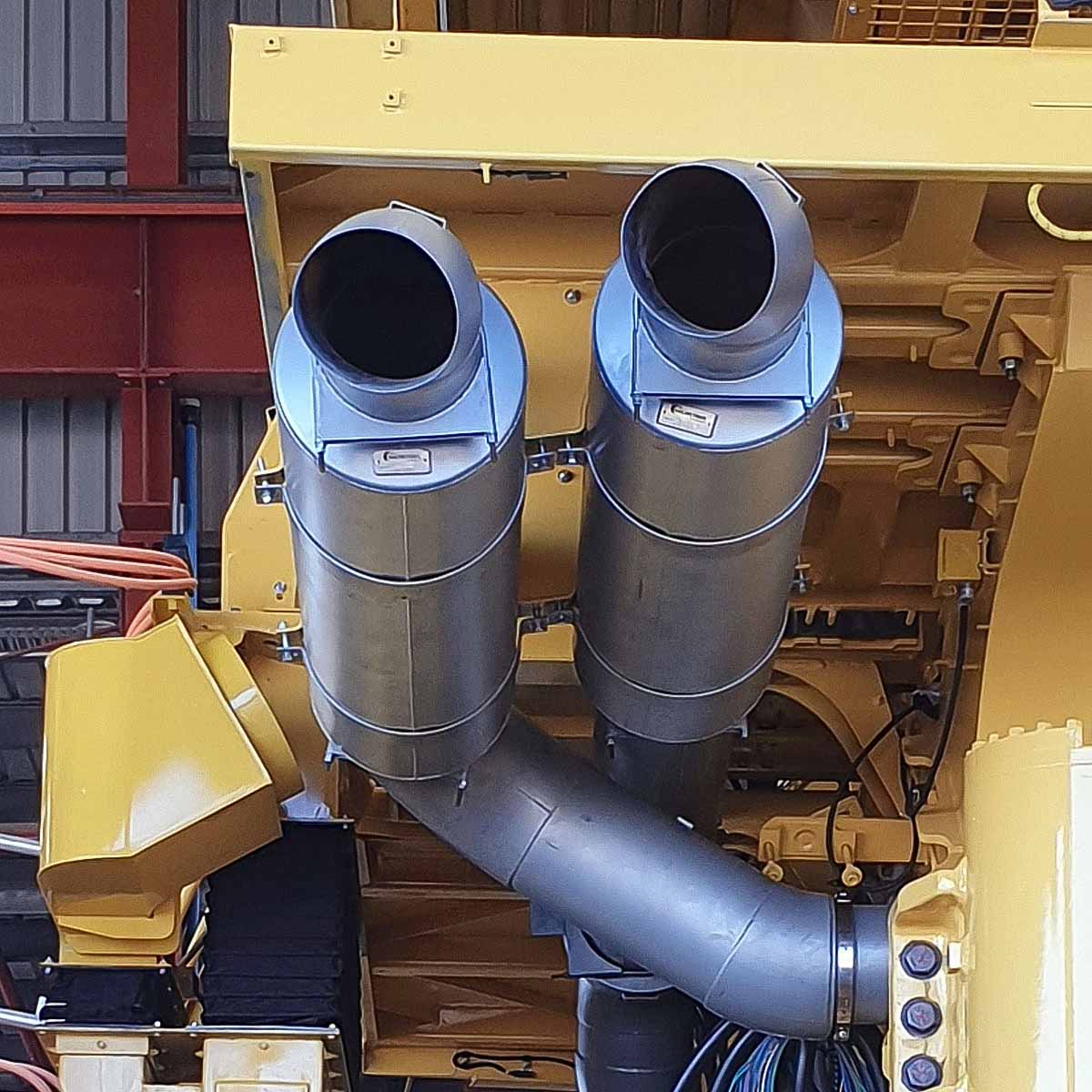

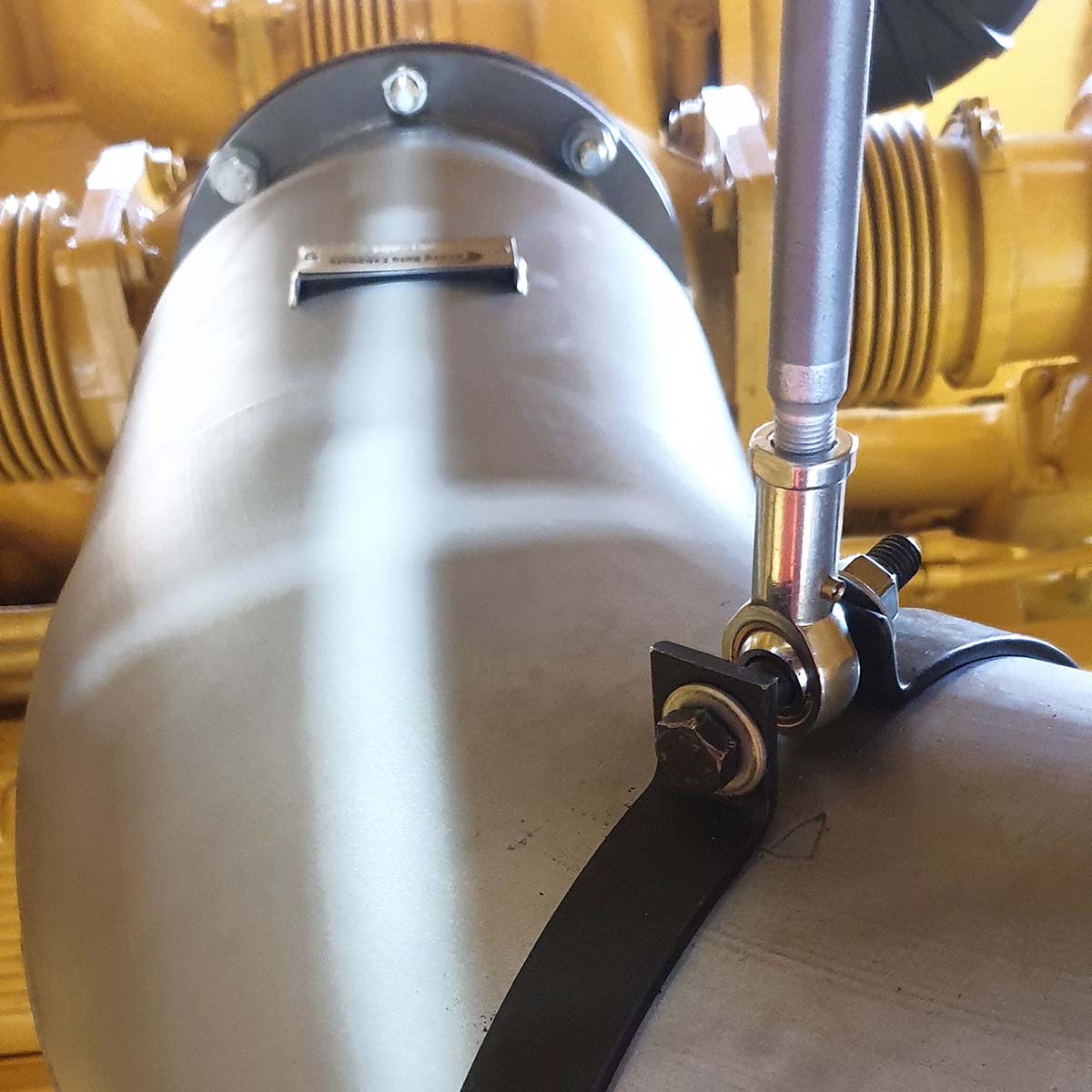

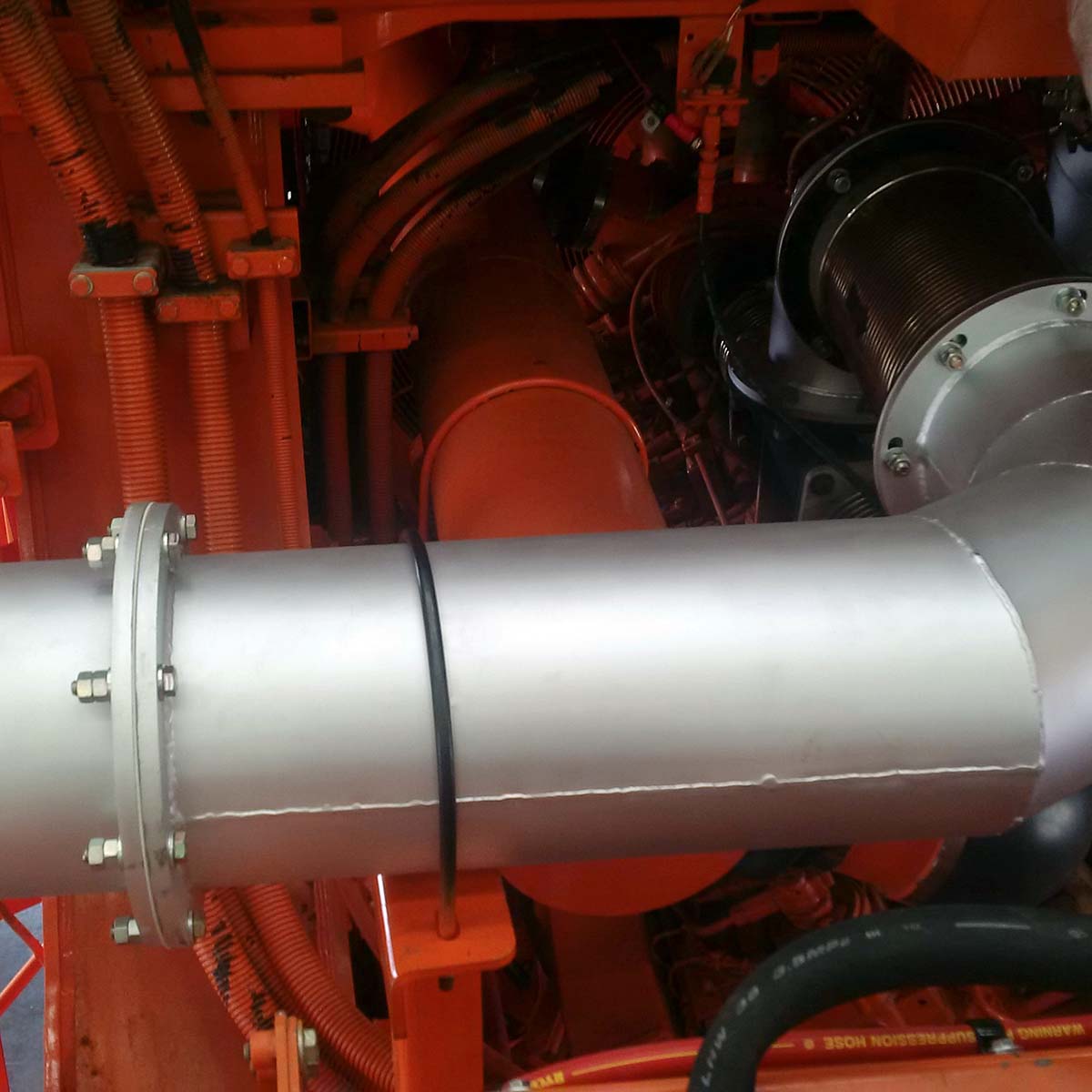

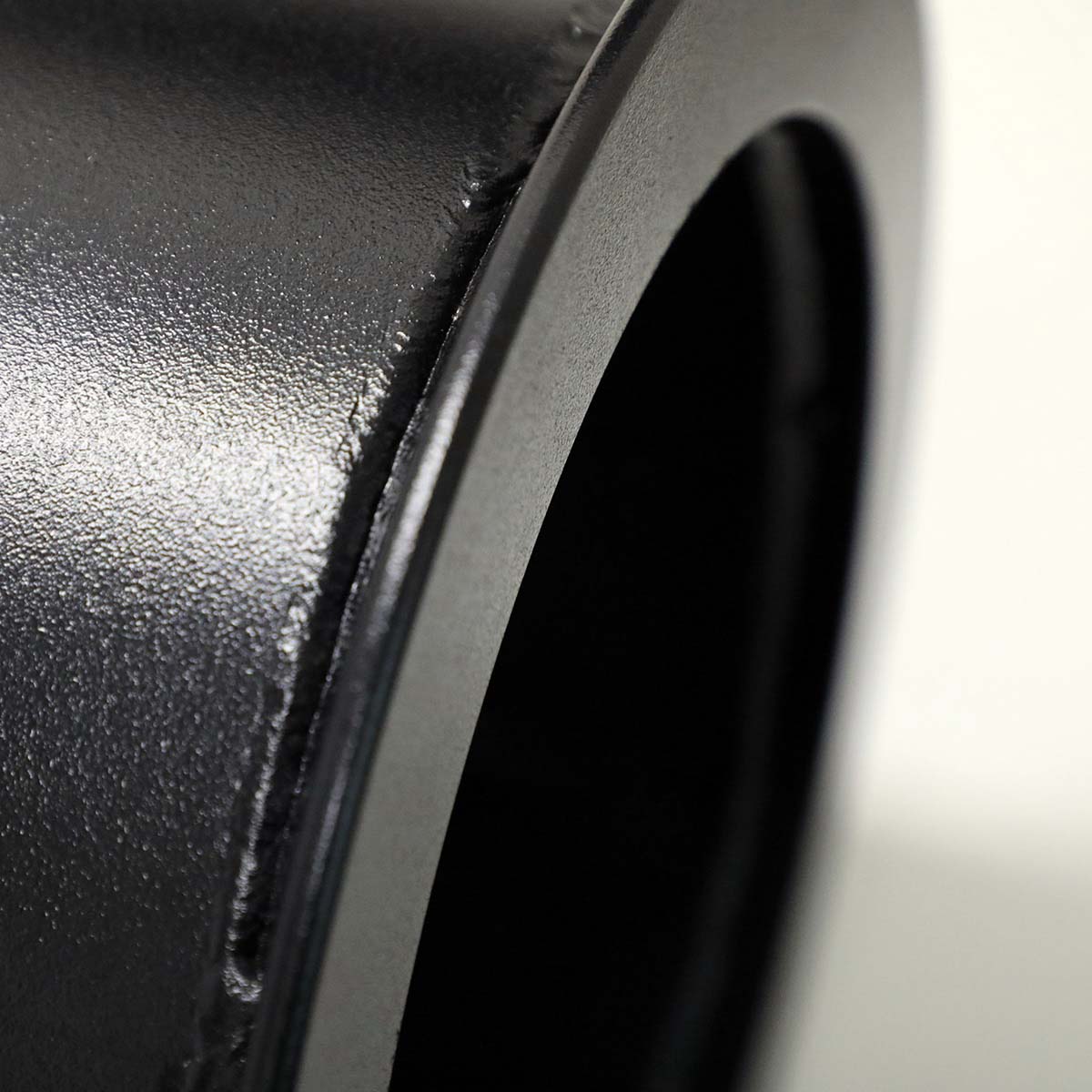

Product Gallery

Explore our range of direct-fit replacement and dual-wall exhaust systems for heavy-duty mining equipment.

Your Questions Answered

Why Choose Our Exhausts?

Our process begins with precision 3D scanning of the original components. This data is used to create master parts and manufacturing jigs, ensuring every exhaust we produce is an exact match to the factory specifications for a seamless, 100% interchangeable fit.

We use premium, heavy-duty materials and incorporate design improvements based on real-world feedback from mine sites. Our skilled fabricators and rigorous quality control at every stage result in a final product that is built for superior longevity and performance in harsh conditions.

Yes. While we have an extensive range of existing parts, our end-to-end process, from 3D scanning to in-house fabrication, allows us to create fully custom solutions tailored to the specific needs and challenges of your fleet.

Consistency is built into our system. By using detailed drawings, manufacturing jigs, and conducting quality inspections at every step of the fabrication process, we ensure that every part is built to the exact same high standard, every single time.