About The Product

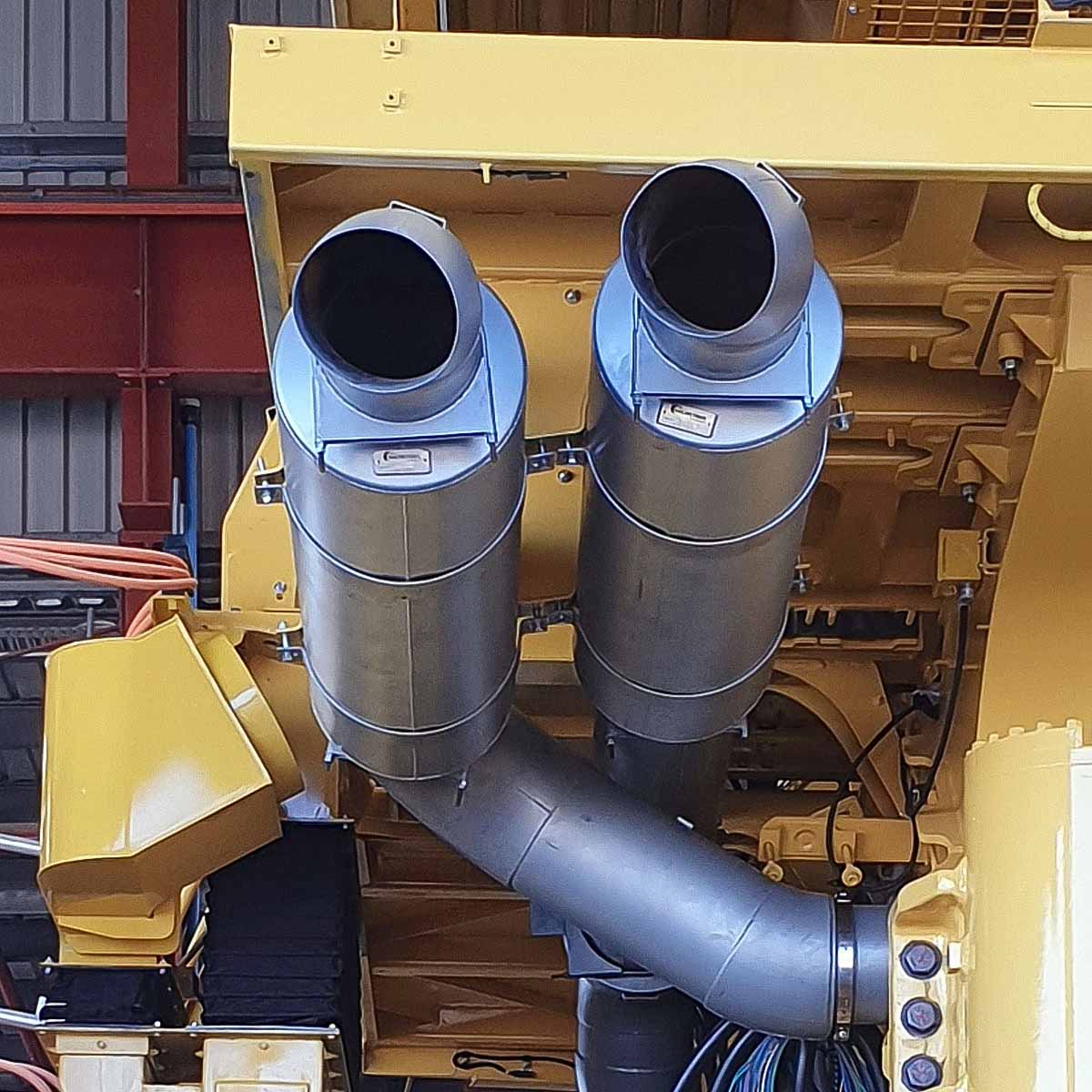

Advanced Dual-Wall Exhaust Technology

A dual-wall exhaust consists of an inner pipe that carries hot exhaust gases, surrounded by an insulated air gap and a durable outer pipe. This innovative design significantly reduces the external surface temperature, mitigating fire risks from contact with flammable fluids. Engineered as a robust, integrated unit, it provides a superior and longer-lasting alternative to conventional lagging or thermal blankets, which are susceptible to damage and saturation.

Precision Engineered

Dual Wall Exhaust Upgrades

A dual wall exhaust system is a strategic component upgrade for mining equipment. Dual wall exhausts are a direct-fit alternative to thermal blankets and lagging. They offer many benefits, such as reducing fire risk, enhancing durability, and simplifying maintenance.

Request a Quote

Built to Last

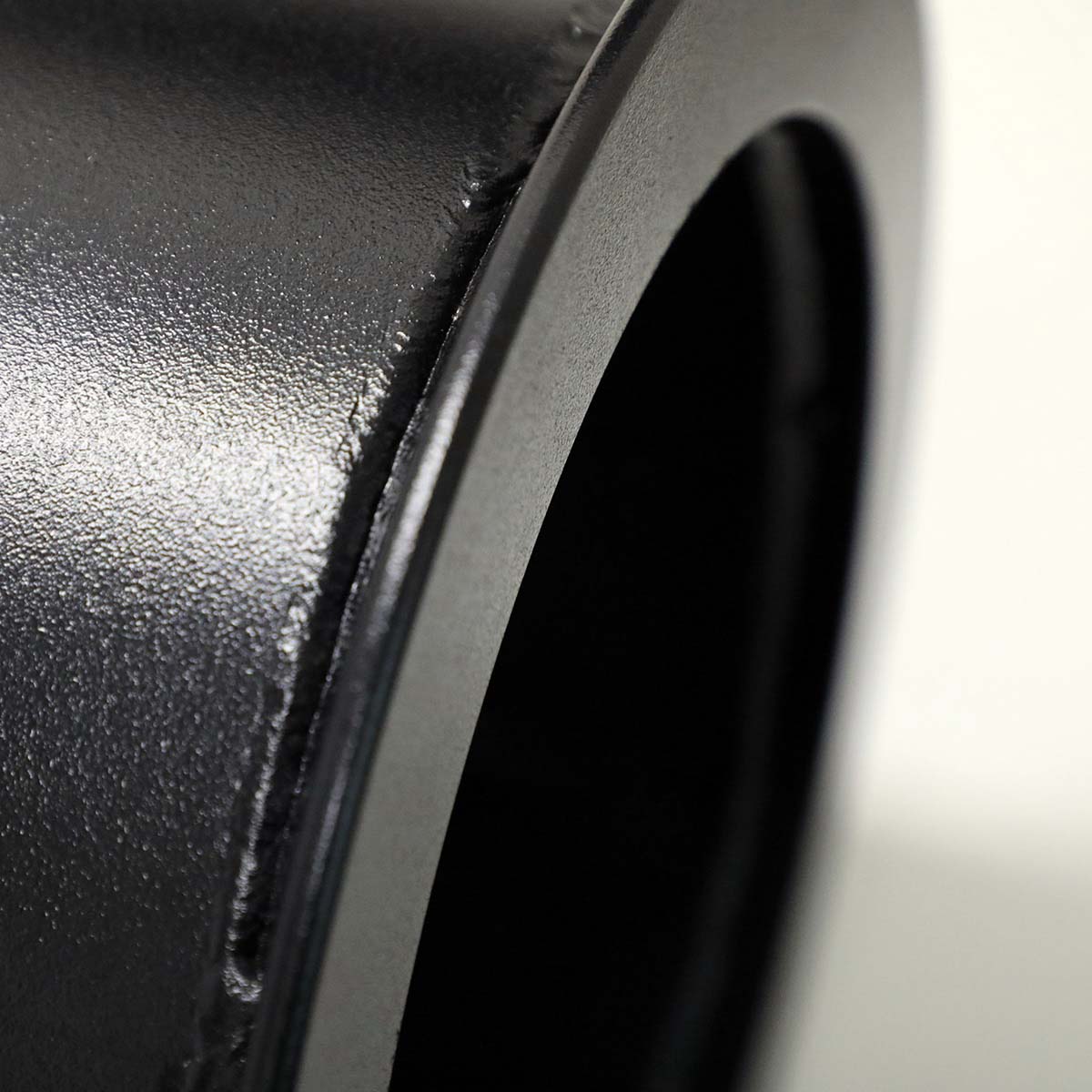

Durability By Design

Our dual wall exhausts are built for endurance and longevity. The outer pipe protects the inner pipe from external damage. We use thicker gauge steel than OEM parts, and our heavy-duty flex bellows are reinforced.

Strategic Advantage

Simplified Maintenance

Dual wall exhausts are more robust than thermal blankets, which are prone to damage and wear. Our dual wall exhausts require less maintenance, and no special tools are required for installation. Improve your uptime with our dual wall exhaust systems.

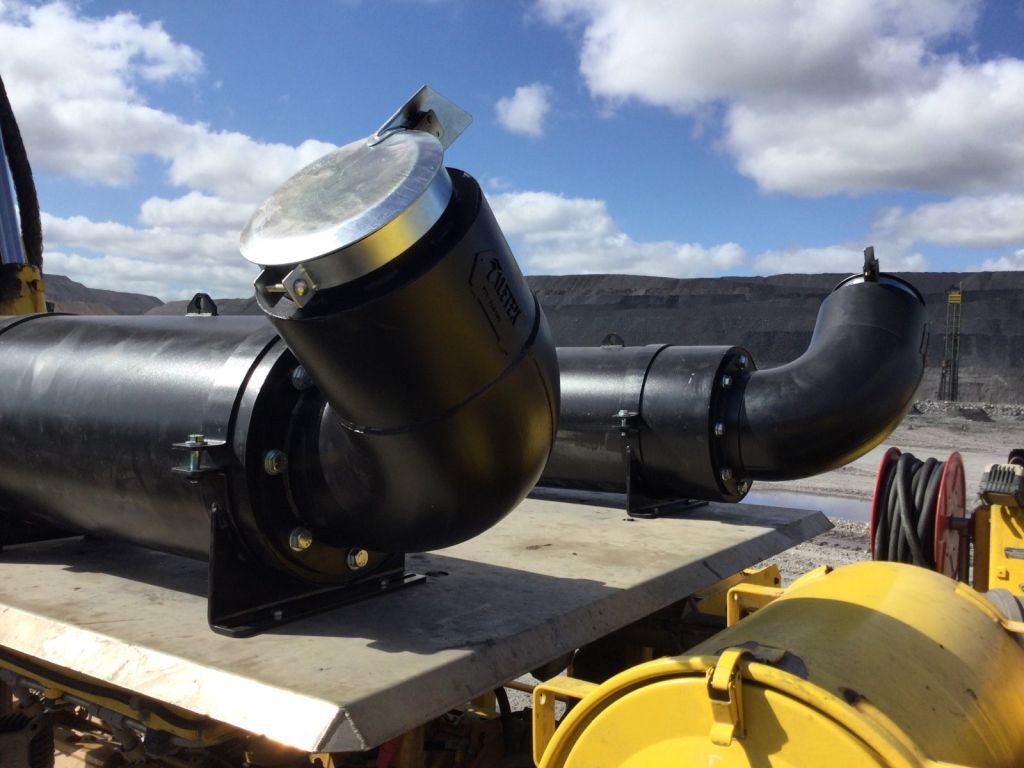

Our Work

Dual Wall Exhaust Gallery

View our range of innovative dual wall exhaust systems, engineered for the toughest mining conditions worldwide.

Your Questions Answered

Why Choose Our Dual-Wall Exhausts?

Unlike thermal blankets that can get torn, saturated with flammable fluids, and require frequent replacement, our dual-wall exhausts are a fully integrated, robust solution. The protective outer pipe prevents damage and contamination, ensuring consistent performance and a much longer service life.

We engineer for longevity by using thicker gauge steel than OEM standards and incorporating heavy-duty, reinforced flex bellows. This construction, combined with the protective outer pipe, provides exceptional resistance to vibration, impacts, and the harsh operational environment of a mine site.

Our dual-wall systems are a 'fit and forget' upgrade. They eliminate the need for regular inspection and replacement of fragile blankets. Because they are a direct-fit installation with no special tools required, they reduce maintenance time and complexity, directly contributing to increased machine availability.

Yes, this is one of their primary benefits. The insulated air gap between the inner and outer pipes dramatically lowers the external surface temperature. This keeps the surface well below the flashpoint of common hydraulic oils and fuels, significantly reducing the risk of a fire starting from a fluid leak.