About The Product

What is Exhaust Backpressure Monitoring?

Exhaust Backpressure Monitoring (EBM) is a critical diagnostic process for managing Diesel Particulate Filters (DPFs). Our rugged EBM data logger continuously records key metrics like backpressure, exhaust gas temperature, and engine RPM. This vital data provides a clear picture of the DPF's health, allowing maintenance teams to move from a reactive to a predictive approach, saving time, money, and preventing unplanned downtime.

Operational Efficiency

Exhaust Backpressure Monitoring (EBM)

Having an EBM system for your DPF is critical for predictive maintenance. By logging key data, you can analyse filter performance, predict service lifecycles, and schedule DPF cleaning before issues arise, ultimately reducing maintenance costs and downtime.

Get Assistance

Data-Driven Maintenance

Why Track DPF Performance?

Monitoring your DPF's performance provides invaluable insights for your maintenance strategy. Tracking this data helps to reduce backpressure issues, lower your Total Cost of Ownership (TCO), and even identify underlying engine issues that could be affecting your DPF's lifecycle and performance.

Built for Mining

Advanced & Rugged System Features

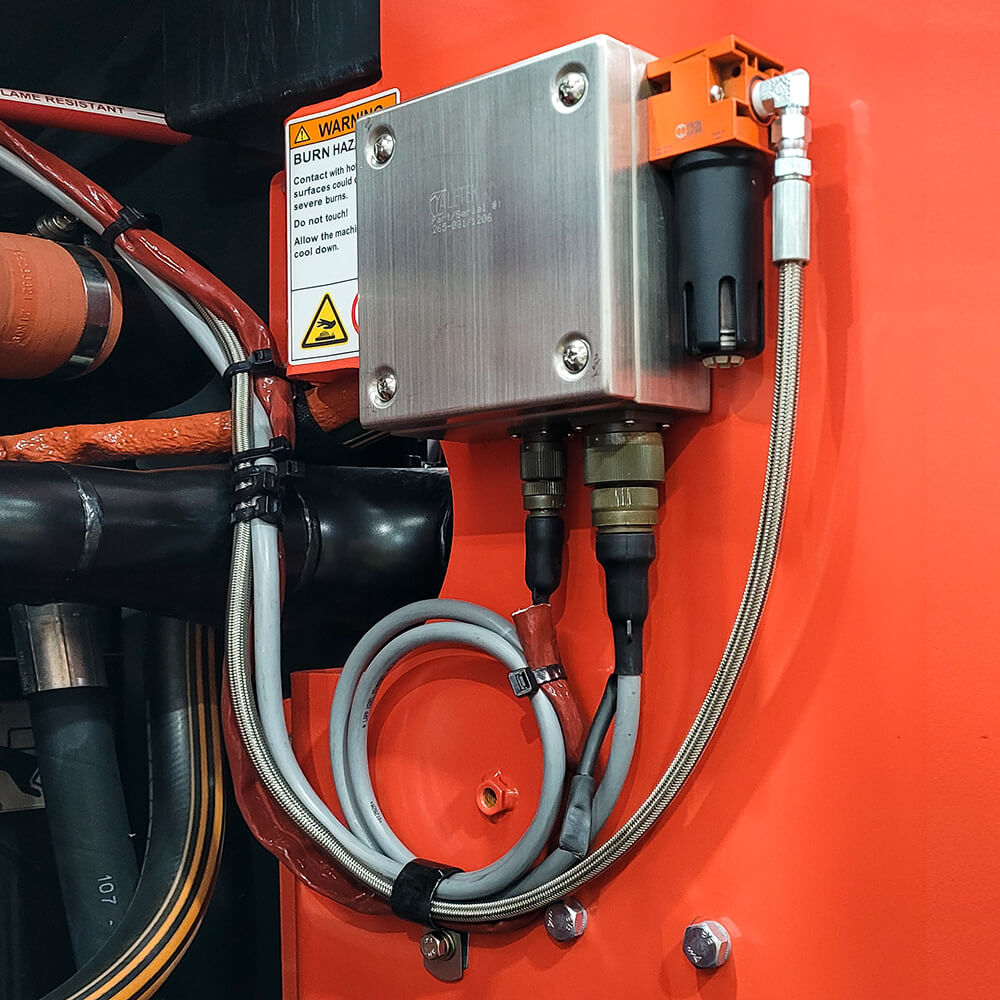

Our EBM system has evolved into a rugged, heavy-duty solution with advanced technology. It features high-speed data transfer, a user-friendly interface, and is housed in an IP66, 316-grade stainless steel enclosure. All components, including thermocouple cables and hoses, are high-temperature and fire-rated for maximum durability.

Your Questions Answered

Why Choose Our EBM System?

The system allows you to see a DPF's health in real-time. Instead of waiting for a filter to block and stop a machine, you can monitor the data, see the trend of increasing backpressure, and schedule a cleaning during a planned maintenance window. This transforms an emergency into a routine task.

Absolutely. It is specifically designed for harsh mining conditions. The data logger is protected by an IP66-rated, 316-grade stainless steel enclosure, and all cables and hoses are fire-rated and shielded to withstand heat, moisture, and vibration.

Efficiency is key. Our system features high-speed data transfer, with most downloads taking less than two minutes. The user-friendly interface makes accessing and analyzing the data straightforward for your maintenance planners and technicians.

Yes. The data from the EBM can be a powerful diagnostic tool. Abnormally high exhaust temperatures or rapidly increasing backpressure can indicate underlying engine problems, such as faulty injectors or turbo issues, allowing you to catch and fix them before they cause major damage.