About The Product

High-Performance OEM DPF Upgrades

An OEM DPF upgrade is more than a standard replacement. It is a strategically engineered solution designed to outperform the original factory filter. We achieve this through a meticulous design process that aligns high-capacity filter substrates with your engine's specific duty cycles and temperatures. The result is a more reliable, durable, and efficient DPF that ensures compliance, maximizes uptime, and protects your workforce.

A Strategic Upgrade

OEM DPF Filter Upgrades for Mining

We rely on superior, high-capacity diesel particulate filters to provide industry-leading DPM filtration for mining fleets. [1] We specialise in equipping underground mines with high-performance, Australian-made DPF upgrades. [1]

Request a Quote

Our Commitment

A Meticulous Design Approach

One size doesn't fit all. We align filter substrates with OEM engine specifications during the technical design phase. [1] With the help of a leading filter supplier, we have developed the perfect substrate catalyst coating for machine duty cycles and temperatures. [1]

Our Commitment

Building a World-Class DPF

Our team designs and builds world-class DPFs. We select the finest raw materials, fabricate flawlessly, and finish with skilled stainless steel pickling. [1]

Our Commitment

Controlled Drawings and Pipe Jigs

A quality-control process ensures consistency at critical stages of the DPF builds. The fabrication process is guided by a drawing system managed by our design team. [1] For direct-fit integration, pipe jigs are essential for replicating OEM exhaust paths. [1]

Our Commitment

Fabricating Impeccable DPFs

Our fabrication process is highly accurate, relying on a lean manufacturing workflow and processes like laser cutting. [1] We use stainless steel pickling to help prevent corrosion. [1] Powder coating and ceramic coating finishes are also available. [1]

Operational Efficiency

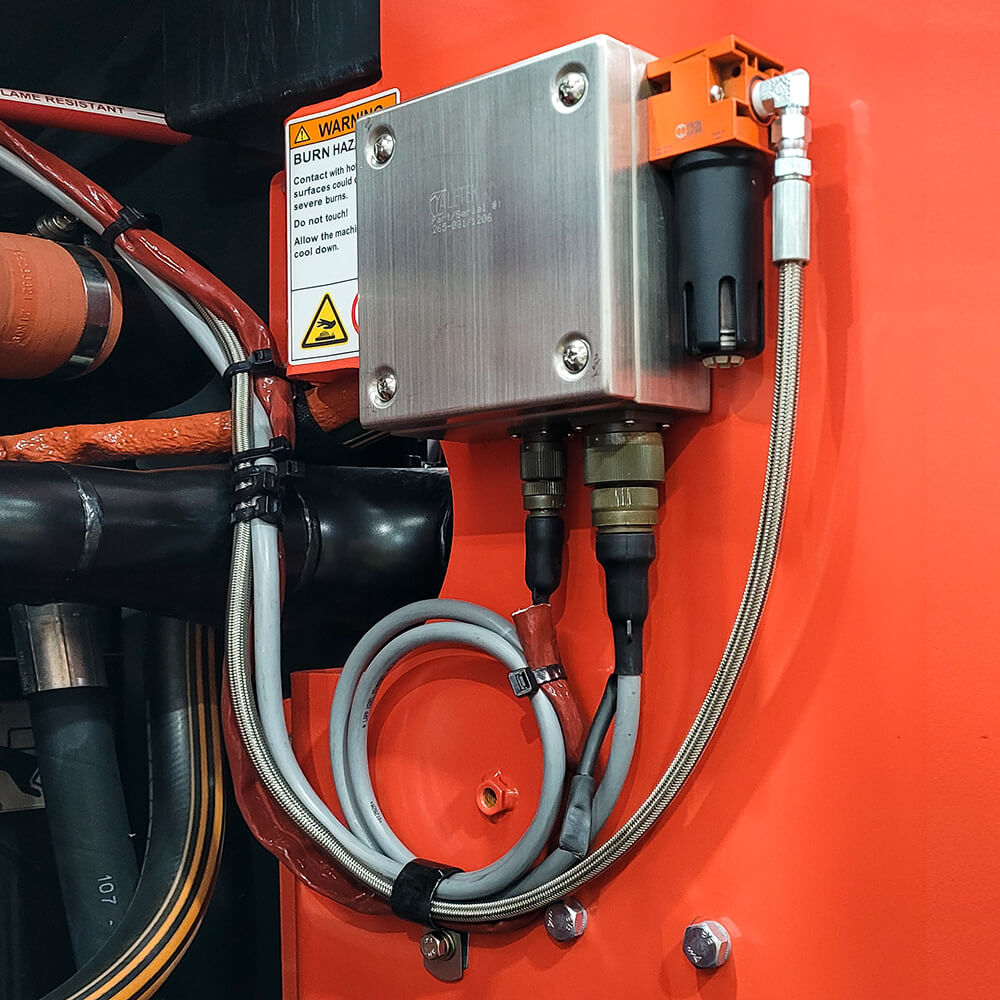

Exhaust Backpressure Monitoring (EBM)

Having an EBM system for your DPF is critical. [1] It records backpressure, exhaust gas temperature, and engine RPM. [1] This data helps predict service lifecycles, schedule DPF cleaning, and analyse filter performance, ultimately reducing maintenance costs and downtime. [1]

Get Assistance

Our Work

DPF Product Gallery

Explore our custom-engineered Diesel Particulate Filters, designed for a range of underground mining equipment.

Your Questions Answered

Why Choose Our DPFs?

It means we don't use a "one-size-fits-all" filter. We carefully select and align the filter substrate and catalyst coating to your specific engine specifications and typical machine duty cycles. This tailored approach results in a DPF that performs more efficiently and lasts longer, directly impacting your fleet's productivity.

Our commitment to quality is embedded in our process. We use controlled drawings for every build, and precision pipe jigs to guarantee a perfect, direct-fit integration with OEM exhaust paths. This, combined with our flawless fabrication and superior raw materials, ensures every DPF is built to the same world-class standard.

Stainless steel pickling is a finishing process that removes impurities and creates a chromium-rich passive layer on the surface. This significantly enhances the corrosion resistance of the DPF housing, making it far more durable in the harsh, corrosive environments common in underground mining.

EBM is the key to proactive DPF management. By giving you real-time data on filter performance, it allows you to predict and schedule maintenance before a problem occurs. This prevents costly unplanned downtime, protects the engine from damage, and ensures your DPF is always operating at peak efficiency for compliance.