About The Product

High-Performance Thermal Insulation Blankets

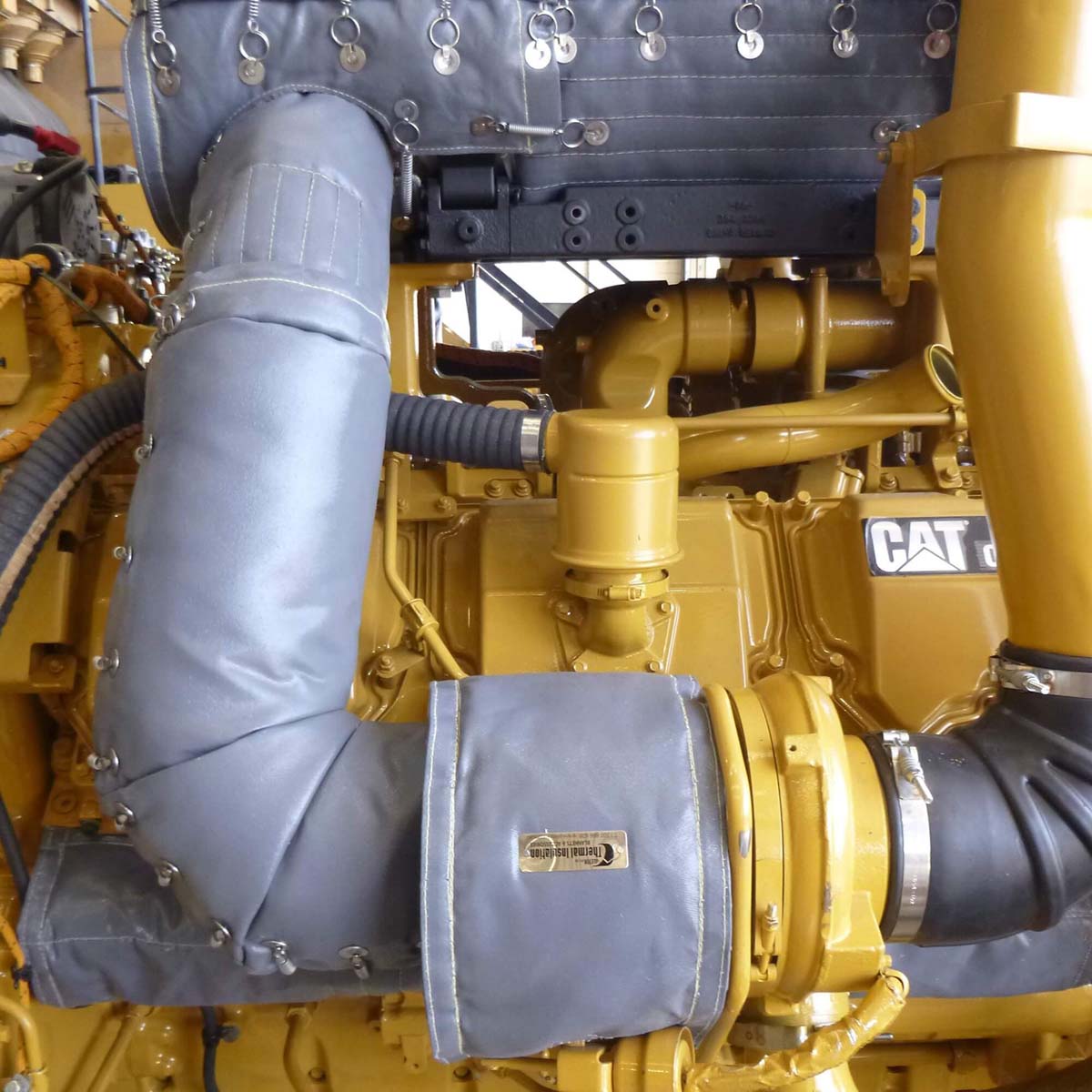

Thermal blankets, also known as lagging kits, are essential safety components for heavy machinery. These multi-layered insulation jackets are custom-designed to wrap around high-temperature engine and exhaust parts like manifolds and turbos. Their primary purpose is to contain extreme heat, drastically reducing external surface temperatures to prevent fires and protect personnel from burns.

Custom Fit

Tailor-Made Thermal Blankets

Our thermal blankets are custom-made for your equipment and are a proven solution that helps protect your crew and assets. We have an extensive range of designs for many makes and models of earthmoving and mining equipment.

Request a Quote

Superior Construction

Thermal Blanket Layers

Our blankets are built tough with multiple layers for durability and performance. They feature a silica insulation mat, stainless steel mesh for strength, and a robust silicone-coated outer layer to withstand harsh conditions.

All-In-One Solution

Complete Blanket Packages

We can create custom lagging solutions for your entire fleet. Full machine and manifold and turbo kits are available. Our team will work with you to create a tailor-made solution that meets your specific requirements.

Extensive OEM Coverage

Supporting Your Entire Fleet

We have developed an extensive library of patterns for a wide range of mobile equipment, covering the world's leading OEMs.

Both surface & underground: Caterpillar, Komatsu (incl. P&H/Joy/GHH), Sandvik, Epiroc, Liebherr.

Primarily surface: Hitachi CM, Volvo CE, Sany, XCMG, Wirtgen Group, Vermeer, Tesmec, BELAZ, Terex/Unit Rig, John Deere.

Primarily underground: Normet, MacLean Engineering, Getman, J.H. Fletcher & Co., Resemin, Aramine, Paus, AARD, Fermel, Boart Longyear, ZMJ, Fambition, Joy (legacy brand), GHH.

Furthermore, we can develop custom lagging kits for any equipment as needed to meet your specific requirements.

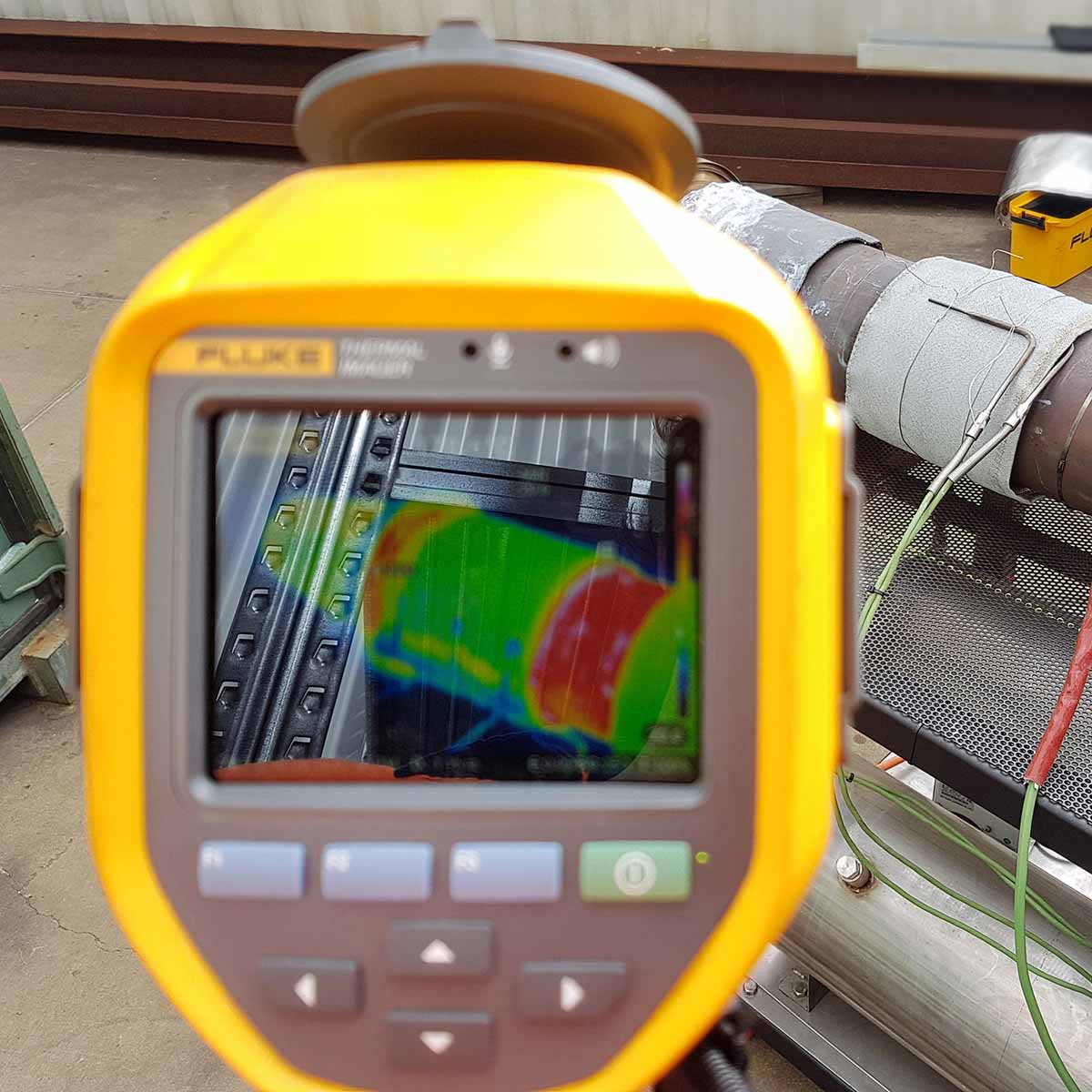

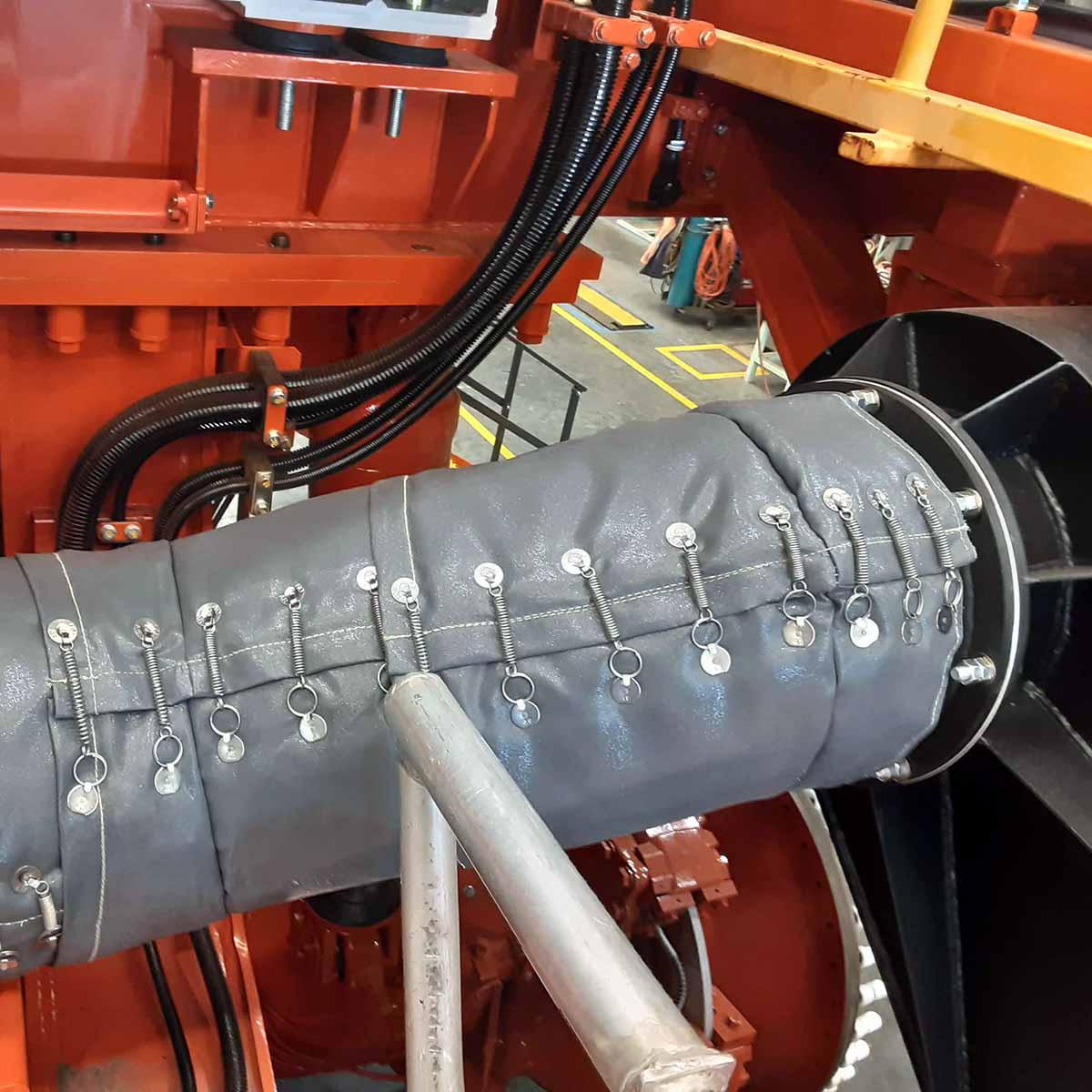

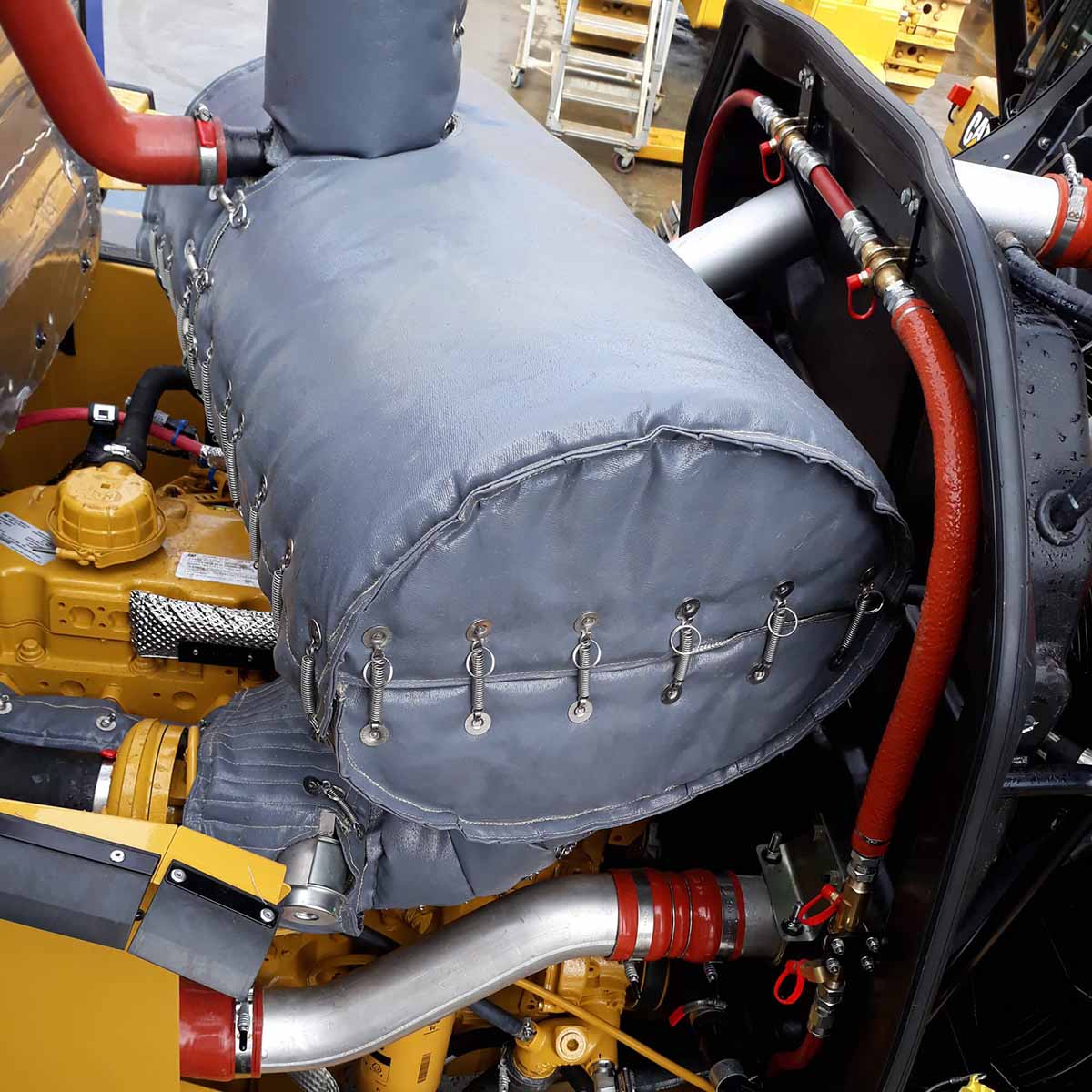

Our Work

Product & Application Gallery

Explore our custom-fit thermal blankets in production and installed on a wide range of heavy machinery.

Your Questions Answered

Why Choose Our Thermal Blankets?

We maintain an extensive digital library of patterns for thousands of OEM parts. For new or custom equipment, our team can 3D scan components on-site to create a precise digital model, guaranteeing a perfect fit that provides maximum coverage and thermal protection.

Our blankets are built with a multi-layer system designed for durability. The inner silica insulation provides excellent heat containment, the stainless steel mesh adds structural strength, and the outer silicone-coated layer resists oil, water, and abrasion, preventing contamination and degradation.

Yes. Our extensive OEM coverage for both surface and underground machinery is one of our key strengths. Whether you run Caterpillar, Komatsu, Liebherr, Sandvik, or a mix of other brands, we can provide complete blanket packages to standardize safety and quality across your entire fleet.

That's not a problem. Our in-house design and manufacturing capabilities allow us to create fully custom lagging kits for any piece of equipment. We will work with you to develop a tailor-made solution from scratch to meet your specific requirements.